Calcined kaolin - high opacity, strength and temperature stability

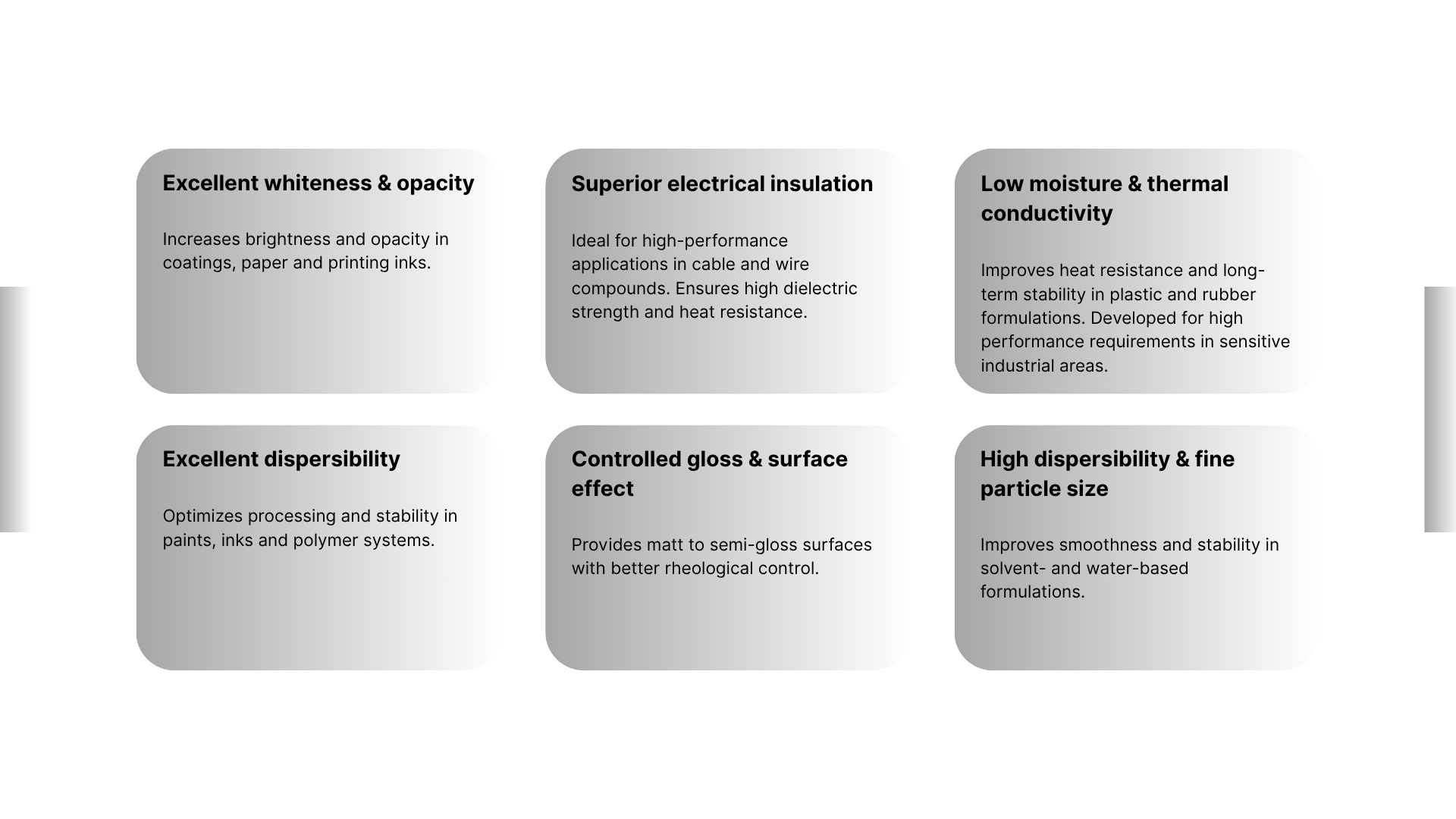

Calcined kaolin is produced through targeted thermal treatment of hydrous kaolin. This changes the structure and function - the product becomes more opaque, harder and more heat-resistant. Ideal for demanding applications in paints, plastics, sealants or paper. It combines technical performance with reliable processability - for systems that have to work.

Paints & Varnishes

Calcined kaolin improves opacity and reduces the amount of titanium dioxide required in paints and varnishes. Thanks to its high degree of whiteness and defined particle structure, it ensures excellent opacity and uniform pigment distribution. It increases mechanical stability and gives matt to silk-matt coatings an elegant surface appearance. In water-based systems, it also acts as a functional rheology modifier.

Ceramics

Calcined kaolin increases the thermal resistance and strength of ceramic products. In tiles, sanitary ceramics and technical applications, it improves the sintering properties and enables precise shaping. The high chemical purity ensures uniform coloration in the firing process. At the same time, it supports efficient drying and reduces cracking.

Cable compounds

For cable and wire compounds, calcined kaolin offers excellent electrical insulation performance. It reduces dielectric losses and supports thermal stability in high-voltage systems. The fine particle distribution enables homogeneous embedding in the polymer matrix. It is particularly used in halogen-free flame retardant (HFFR) systems due to its chemical inertness and thermal stability.

Plastics

In plastic applications, calcined kaolin acts as a multifunctional filler to improve mechanical strength and thermal resistance. It reduces shrinkage and increases dimensional stability. It also optimizes the surface finish and increases scratch resistance in visible parts. It is particularly suitable for PP, PE and PVC systems in technical applications.

Paper

In paper production, calcined kaolin serves as an effective filler to increase the brightness and opacity of high-quality papers. It improves printability and reduces the transparency of thin papers. Thanks to its thermal treatment, it offers excellent dimensional stability in heat-stressed finishing processes. It is a proven whitener, especially in high-quality packaging solutions and printing papers.